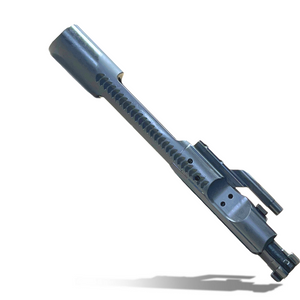

FDE PVD BCG- chrome lined carrier

- M16 Auto Profile Carrier Machined from Aircraft/ Bearing Quality 8620 Steel, Properly Heat Treated, Ground to Perfection, FDE PVD Finish

- Bolt is machined from a single piece of 9310 steel, heat treated properly, precision ground, Shot Peened and MPI’d, FDE PVD finish

- Firing pin is machined to the mil-spec print from 8740, precision ground, and chrome plated

- One Piece Billet Fully Machined Enhanced Extractor, Phosphate coated for Increased reliability and corrosion resistance

- PVD Cam Pin

- S7 tool steel ejector and extractor retaining pin

- 4130 Gas Key, precision staked using our hydraulic staking machine,PVD finish

- KAK Carrier Key Screws- T25 drive, Grade 8, Properly Heat Treated

PVD (Physical Vapor Deposition) coating is a process used to apply thin films or coatings to surfaces, offering a range of benefits depending on the material and application. PVD is widely used in various industries, including aerospace, firearms, and manufacturing, due to its ability to improve surface properties such as hardness, corrosion resistance, and aesthetic appearance.

How PVD Works

- Vaporization: A material (typically a metal or metal compound) is vaporized in a vacuum chamber. This can be done using techniques like sputtering or evaporation.

- Deposition: The vaporized material then condenses onto the substrate (the surface being coated) to form a thin, solid film.

- Bonding: The coating adheres to the substrate surface, forming a durable layer.

Benefits of PVD Coatings

- Durability: PVD coatings are known for their hardness and wear resistance, which makes them ideal for applications where surfaces are subject to friction or abrasion.

- Corrosion Resistance: They provide excellent protection against corrosion, extending the lifespan of the coated materials.

- Aesthetic Appeal: PVD coatings can be applied in various colors and finishes, which is often used for decorative purposes in addition to functional ones.

- Hand:

- Right Hand

- Platform:

- AR15

- Caliber:

- 5.56

- Type:

- STANDARD BCG

- Finish Type:

- FDE PVD

- Vent Type:

- Side Vent